+22

davecb5002

tt fan

russellj

l.t.racing

Llewelyn1965

mart

trophydave

bikermikey1

ceejay

sullivj

Beresford

eternally_troubled

Tricky.

ANDYC

ratatooie

rwhitton

Mad_Taffy_500

jerryfudd

scottrichardwalker

ashcroc

wornsprokets

Jameshambleton

26 posters

My Track bike project

Beresford- the 900

- Posts : 1861

Location : not that far from Kirkistown

- Post n°101

Re: My Track bike project

Re: My Track bike project

It's just that a bellmouth of some sort is necessary for non-turbulent flow into the carb venturi. Also the length of the tract from inlet valve head to bellmouth lip is somewhat critical for your target rev range.

ANDYC- the 900

Posts : 1300

Location : Windsor

- Post n°102

Re: My Track bike project

Re: My Track bike project

The adapter acts like a venturi, it's just more stable to clamp the filters to. A shorter venturi is better for higher revs.

ANDYC- the 900

Posts : 1300

Location : Windsor

- Post n°103

Re: My Track bike project

Re: My Track bike project

Headway is being made, slowly but nevertheless

One of the filter adapters arrived, the other one has to come from America.

The carbs are now linked together and have a common operating rod. I wanted to keep the profile of the carbs as low as possible to give me clearance for the underside of the fuel tank. Hence the cable linkage is at the side where I have plenty of clearance.

On to the exhaust side now. As they say what goes in has to come out, so I have gone for large bore header pipes which will be held on to the head with springs rather than the conventional stud/bolt/flange method.

For this reason I had to machine a pair of spigots that do bolt onto the head (but they will stay fixed there) to locate the headers.

They were turned and bored out of 75mm solid steel bar. The last picture has a piece of the pipe that will be used to make the 2-1 system. It was handy to have a spare cylinder head to test fit them to.

Not sure what finish to put on the finished headers yet, I probably will leave such decisions until I can see it actually on the bike.

One of the filter adapters arrived, the other one has to come from America.

The carbs are now linked together and have a common operating rod. I wanted to keep the profile of the carbs as low as possible to give me clearance for the underside of the fuel tank. Hence the cable linkage is at the side where I have plenty of clearance.

On to the exhaust side now. As they say what goes in has to come out, so I have gone for large bore header pipes which will be held on to the head with springs rather than the conventional stud/bolt/flange method.

For this reason I had to machine a pair of spigots that do bolt onto the head (but they will stay fixed there) to locate the headers.

They were turned and bored out of 75mm solid steel bar. The last picture has a piece of the pipe that will be used to make the 2-1 system. It was handy to have a spare cylinder head to test fit them to.

Not sure what finish to put on the finished headers yet, I probably will leave such decisions until I can see it actually on the bike.

russellj- Newbie

- Posts : 1

- Post n°104

Re: My Track bike project

Re: My Track bike project

dear Andy,I have been reading track bike project article,fantastic reading,you say you break bikes now!I would love to speak to you,my contact no is 0785 800 1995,I live at Carlisle its a shame I am 300mls up the road from you!

Hope to hear from you,

Kind regards,

Russell Jones.

Hope to hear from you,

Kind regards,

Russell Jones.

ANDYC- the 900

Posts : 1300

Location : Windsor

- Post n°105

Re: My Track bike project

Re: My Track bike project

I haven't been able to do much recently due to time constraints etc, but I did manage to convert a lump of billet aluminium into a manual cam chain tensioner yesterday afternoon.

It's not completely finished yet as I'm waiting for the steel thread insert (m10 x 1.25) to finish the thread to the correct size, and I may or may not finish the shape to the same lines as the original.

I think the exhaust will be the next stage to tackle.

I do have a set of 74mm Wiseco pistons on their way to me from America along with a set of forged con rods.

They may be for a later stage in the project development, I'm just quite keen to get it up and running now.

I would prefer it to be functional rather than in it's present ornamental state

It's not completely finished yet as I'm waiting for the steel thread insert (m10 x 1.25) to finish the thread to the correct size, and I may or may not finish the shape to the same lines as the original.

I think the exhaust will be the next stage to tackle.

I do have a set of 74mm Wiseco pistons on their way to me from America along with a set of forged con rods.

They may be for a later stage in the project development, I'm just quite keen to get it up and running now.

I would prefer it to be functional rather than in it's present ornamental state

ANDYC- the 900

Posts : 1300

Location : Windsor

- Post n°106

Re: My Track bike project

Re: My Track bike project

Just made up a blanking plug to seal off the opening for the standard water pump as I plan to use an electric pump.

The 74mm wiseco pistons arrived all well and good, new rings are also on their way from the states.

It doesn't seem like much progress but it's progress none the less.

The 74mm wiseco pistons arrived all well and good, new rings are also on their way from the states.

It doesn't seem like much progress but it's progress none the less.

Beresford- the 900

- Posts : 1861

Location : not that far from Kirkistown

- Post n°107

Re: My Track bike project

Re: My Track bike project

The electric pump is an intriguing idea. What make will you be using? It will be interesting to see your installation.

tt fan- Silver Bullet

- Posts : 111

Location : Cambridge

- Post n°108

Re: My Track bike project

Re: My Track bike project

Fascinating read, i keep looking in here.

Any more progress Andy?

Any more progress Andy?

ANDYC- the 900

Posts : 1300

Location : Windsor

- Post n°109

Re: My Track bike project

Re: My Track bike project

At present the bike is away having an exhaust specially built for it. I'm looking forward to getting it back in a week or so.

I haven't made much more progress with it due to a number of things, but until the exhaust was built I couldn't decide on which fairing to use. Which meant that I couldn't decide on which clocks to use, which in turn delays me building the loom. You get the picture, one thing leads to another.

The cylinders were bored to 74mm (+1mm) and I'm ready to build the engine now, all I need is time to do it which seems to be elusive at the moment.

This afternoon I'm modifying the carb linkages to make syncronising them easier, and also adjusting the accelerator pumps stroke.

I have been looking into a big valve conversion and have sourced some stainless steel one piece custom built valves that are +1mm, not cheap especially once you have to re cut the valve seats and while I'm at it I may as well replace the valve guides for shorter ones to allow for more valve lift.

I may leave that until the engine has been tested on standard sizes so I have a comparison figure to see what the difference is and is it worth it?

I haven't made much more progress with it due to a number of things, but until the exhaust was built I couldn't decide on which fairing to use. Which meant that I couldn't decide on which clocks to use, which in turn delays me building the loom. You get the picture, one thing leads to another.

The cylinders were bored to 74mm (+1mm) and I'm ready to build the engine now, all I need is time to do it which seems to be elusive at the moment.

This afternoon I'm modifying the carb linkages to make syncronising them easier, and also adjusting the accelerator pumps stroke.

I have been looking into a big valve conversion and have sourced some stainless steel one piece custom built valves that are +1mm, not cheap especially once you have to re cut the valve seats and while I'm at it I may as well replace the valve guides for shorter ones to allow for more valve lift.

I may leave that until the engine has been tested on standard sizes so I have a comparison figure to see what the difference is and is it worth it?

ANDYC- the 900

Posts : 1300

Location : Windsor

- Post n°110

Re: My Track bike project

Re: My Track bike project

Just a bit of an update,

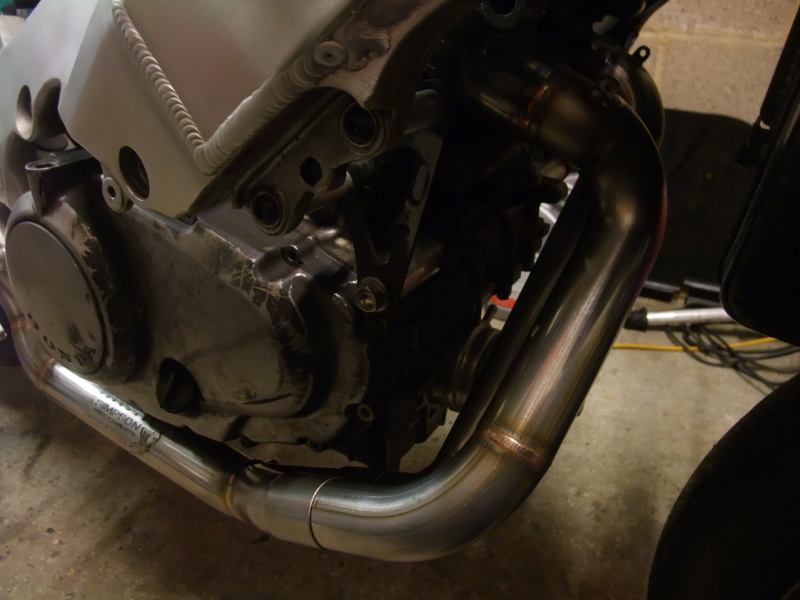

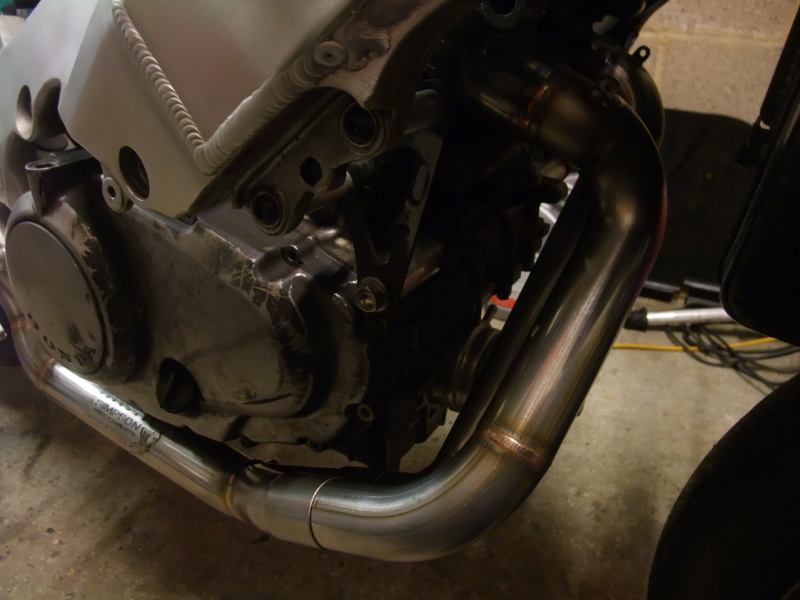

I now have the bike back with new exhaust, built just how I wanted it.

Even down to the positioning of the oxygen (lambda) sensor.

That's a refreshing change as normally if I wanted something done to my spec I have to build it myself.

Now I can get on with the rest of it.

I now have the bike back with new exhaust, built just how I wanted it.

Even down to the positioning of the oxygen (lambda) sensor.

That's a refreshing change as normally if I wanted something done to my spec I have to build it myself.

Now I can get on with the rest of it.

davecb5002- Mothra the Radioactive

- Posts : 221

Location : OSWESTRY SHROPSHIRE

- Post n°111

Re: My Track bike project

Re: My Track bike project

That looks very smart and profesional

ANDYC- the 900

Posts : 1300

Location : Windsor

- Post n°112

Re: My Track bike project

Re: My Track bike project

The guys that built it do race exhausts for a living. Up close it's a work of art, ok it's not polished but that wasn't what I wanted anyway .

tt fan- Silver Bullet

- Posts : 111

Location : Cambridge

- Post n°113

Re: My Track bike project

Re: My Track bike project

That's looking great.

Very neat bit of tig.

Can you tell us much about the frame?

Very neat bit of tig.

Can you tell us much about the frame?

ANDYC- the 900

Posts : 1300

Location : Windsor

- Post n°114

Re: My Track bike project

Re: My Track bike project

The frame is from an nc29. The standard frame was very restrictìve regarding the carb set up and heavier too.

ZekeVal- Running out of unique names

- Posts : 189

Location : Poitiers, France.

- Post n°115

Re: My Track bike project

Re: My Track bike project

That header-pipe looks sweet!!

Hope she runs soon.

Hope she runs soon.

ANDYC- the 900

Posts : 1300

Location : Windsor

- Post n°116

Re: My Track bike project

Re: My Track bike project

I wasn't sure if I had taken the headers out too wide at first. It was necessary to clear the oil cooler, but I'm happy with the outcome now I can see it in the metal.

ANDYC- the 900

Posts : 1300

Location : Windsor

- Post n°117

Re: My Track bike project

Re: My Track bike project

Time for a bit of an update,

the rear wheel is now a 5" rim from a cbr600f3 as it improved the profile of the tyre a lot.

What did suprise me is that this set-up is only a few ounces heavier than the nc29 set-up.

I'll be making alloy spacers to replace the standard steel ones, including the internal one for the bearings. Once done the rear wheel/ brake and suspension can be considered as done.

This is now waiting for collection after powder coating, along with the front calipers that I decided were letting the show down by showing their age.

The calipers will be rebuilt on their return and apart from servicing the forks that part of the front end will be done.

The seat unit is now a Honda rsw250 unit, it looks much better than the nc29 one that I had on it previously.

The tank will be a plastic one based on a cbr600rr one that I'm presently working on, it will have a bottom welded and bonded into it to provide clearance and an epoxy lining as an extra safeguard against leaks.

The fairing I'm still not sure of, the tyga RCV211 style one was my favourite choice but at £800 it was more than I wanted to shell out at the moment. Especially as I wasn't sure how the heat from the downpipes may affect it. I have ordered a top race fairing to fit a cbr600rr3/4(a fifth of the price of the tyga one) and I'll see how that looks and fits in with the rest of the bike. I quite like the idea of not bothering with a bellypan so that the engine is visible. What do you guys think?

The carbs are slowly taking shape, It has taken 10 months to get them from Keihin in California as they kept sending the wrong ones. However I now have two matching filter adapters and can progress with the rest of it. The next step is to machine two separate operating spindles rather than one common one and connect them with a more conventional synchronizing system like the one on the standard cb500 carbs, to simplify balancing the carbs.

Not sure if anyone noticed on the last pictures but I've decided that it could be benefical for me to run an oil/water cooler due to the extra power and higher revs that I'm looking for. This was from an nc29 that I just happened to be breaking. It's also why the exhaust pipes are well clear of it, I did specify that to the guys building the exhaust at the time. Cooler oil can only help in the reliability stakes I think.

I'll get some pictures up when I have the rear wheel and calipers back on it, I do believe that it's begining to take shape at last

the rear wheel is now a 5" rim from a cbr600f3 as it improved the profile of the tyre a lot.

What did suprise me is that this set-up is only a few ounces heavier than the nc29 set-up.

I'll be making alloy spacers to replace the standard steel ones, including the internal one for the bearings. Once done the rear wheel/ brake and suspension can be considered as done.

This is now waiting for collection after powder coating, along with the front calipers that I decided were letting the show down by showing their age.

The calipers will be rebuilt on their return and apart from servicing the forks that part of the front end will be done.

The seat unit is now a Honda rsw250 unit, it looks much better than the nc29 one that I had on it previously.

The tank will be a plastic one based on a cbr600rr one that I'm presently working on, it will have a bottom welded and bonded into it to provide clearance and an epoxy lining as an extra safeguard against leaks.

The fairing I'm still not sure of, the tyga RCV211 style one was my favourite choice but at £800 it was more than I wanted to shell out at the moment. Especially as I wasn't sure how the heat from the downpipes may affect it. I have ordered a top race fairing to fit a cbr600rr3/4(a fifth of the price of the tyga one) and I'll see how that looks and fits in with the rest of the bike. I quite like the idea of not bothering with a bellypan so that the engine is visible. What do you guys think?

The carbs are slowly taking shape, It has taken 10 months to get them from Keihin in California as they kept sending the wrong ones. However I now have two matching filter adapters and can progress with the rest of it. The next step is to machine two separate operating spindles rather than one common one and connect them with a more conventional synchronizing system like the one on the standard cb500 carbs, to simplify balancing the carbs.

Not sure if anyone noticed on the last pictures but I've decided that it could be benefical for me to run an oil/water cooler due to the extra power and higher revs that I'm looking for. This was from an nc29 that I just happened to be breaking. It's also why the exhaust pipes are well clear of it, I did specify that to the guys building the exhaust at the time. Cooler oil can only help in the reliability stakes I think.

I'll get some pictures up when I have the rear wheel and calipers back on it, I do believe that it's begining to take shape at last

Jameshambleton- the 900

- Posts : 2969

Location : Bedale, North Yorkshire

- Post n°118

Re: My Track bike project

Re: My Track bike project

I've never really understood oil coolers, my vfr has one and it's tiny (3 channels high, 17cm long ) I couldn't imagine it would make much difference to the temp of the oil overall.

ANDYC- the 900

Posts : 1300

Location : Windsor

- Post n°119

Re: My Track bike project

Re: My Track bike project

Time for a bit of an update which is long overdue.

The engine went together nicely, only thing that I didn't forsee only became apparent when the engine is on the bench.

The coolant take off on the rear of the cylinder head is blocked by the different carbs so I'll have to fabricate one that comes out straight rather than at an angle.

The sump is still off whilst awaiting ARP stainless crankshaft bearing bolts coming from America, and the clutch is not on yet as I'm still deliberating on a new oil pump although there's nothing wrong with this one. It will probably be down to cost, isn't everything.

The starter motor is one of the few areas where I have conceeded the weight saving and added a few ounces in fitting a 929 fireblade one, I thought the extra power will come in handy to cope with the higher compression. After all if I cant get the thing started it will be an expensive doorstop.

I have gone for a larger alloy race radiator purely because I could.

The fairing is a race one for a CBR600rr4, it may not be the final choice but it gives me something to work with at the moment and helps me visualise the size etc.

The engine went together nicely, only thing that I didn't forsee only became apparent when the engine is on the bench.

The coolant take off on the rear of the cylinder head is blocked by the different carbs so I'll have to fabricate one that comes out straight rather than at an angle.

The sump is still off whilst awaiting ARP stainless crankshaft bearing bolts coming from America, and the clutch is not on yet as I'm still deliberating on a new oil pump although there's nothing wrong with this one. It will probably be down to cost, isn't everything.

The starter motor is one of the few areas where I have conceeded the weight saving and added a few ounces in fitting a 929 fireblade one, I thought the extra power will come in handy to cope with the higher compression. After all if I cant get the thing started it will be an expensive doorstop.

I have gone for a larger alloy race radiator purely because I could.

The fairing is a race one for a CBR600rr4, it may not be the final choice but it gives me something to work with at the moment and helps me visualise the size etc.

Jameshambleton- the 900

- Posts : 2969

Location : Bedale, North Yorkshire

- Post n°120

Re: My Track bike project

Re: My Track bike project

Will be interested to see what you do with the oil cooler, cbr1000 I'm guessing?

How does it work exactly?

How does it work exactly?

ANDYC- the 900

Posts : 1300

Location : Windsor

- Post n°121

Re: My Track bike project

Re: My Track bike project

It's actually from an nc29 the fireblade used a larger one that doesn't fit our crankcases.

It's a water/oil transfer cooler. The water cools down the oil which gets much hotter than the water does.

It's less prone to all the inherent problems with oil/ air coolers.

It's a water/oil transfer cooler. The water cools down the oil which gets much hotter than the water does.

It's less prone to all the inherent problems with oil/ air coolers.

l.t.racing- Four's a...something...

- Posts : 150

- Post n°122

Re: My Track bike project

Re: My Track bike project

Ti engine bolts aswell.have you blanked the water pump off. I love saving weight got mine down to 149kg wet but no fuel. And still got 2.5kg too remove next week. I sooner want them carbs

ANDYC- the 900

Posts : 1300

Location : Windsor

- Post n°123

Re: My Track bike project

Re: My Track bike project

Unfortunately the carbs wont fit in the standard frame Lee, hence the frame change.

The water pump opening has indeed been blanked off, the drive for it has also been removed by shortening the oil pump spindle.

The water pump opening has indeed been blanked off, the drive for it has also been removed by shortening the oil pump spindle.

ANDYC- the 900

Posts : 1300

Location : Windsor

- Post n°124

Re: My Track bike project

Re: My Track bike project

Bit of and update on recent progress.

The ARP stainless crankshaft bearing bolts arrived today, I wasn't taking any chances as I had one shear on me years back which scrapped the crankcases, and that was using a torque wrench to only 25Nm!

I also got around to fitting the clutch, I'm trying to resolve the backplate/ basket spring issue too.

The springs bearing directly on aluminium never impressed me so I'm switching to rubber as an experiment.

Hopefully if my research was successful this kind of rubber will withstand the enviroment with the heat and oil.

It will also quieten down the irritating rattle.

Time will tell

The ARP stainless crankshaft bearing bolts arrived today, I wasn't taking any chances as I had one shear on me years back which scrapped the crankcases, and that was using a torque wrench to only 25Nm!

I also got around to fitting the clutch, I'm trying to resolve the backplate/ basket spring issue too.

The springs bearing directly on aluminium never impressed me so I'm switching to rubber as an experiment.

Hopefully if my research was successful this kind of rubber will withstand the enviroment with the heat and oil.

It will also quieten down the irritating rattle.

Time will tell

Beresford- the 900

- Posts : 1861

Location : not that far from Kirkistown

- Post n°125

Re: My Track bike project

Re: My Track bike project

Are you happy that those runs of lock wire will withstand the centrifugal forces loading them at 10,000+rpms?

|

|

|